The automotive sector has been among the most innovative when compared to other sectors and in the recent years, 3D printing technology has played a significant role in the way car parts are produced. With the enhancement of design flexibility to the lower cost of production, the 3D printed car part is ushering in a new era of cars being made. However, what are 3D printed car parts and why are they so trending? Now, we will enter the realm of 3D printing of car components and see how this technology is transforming the stages of designing, production, and sale of vehicles.

What Are 3D Printed Car Parts?

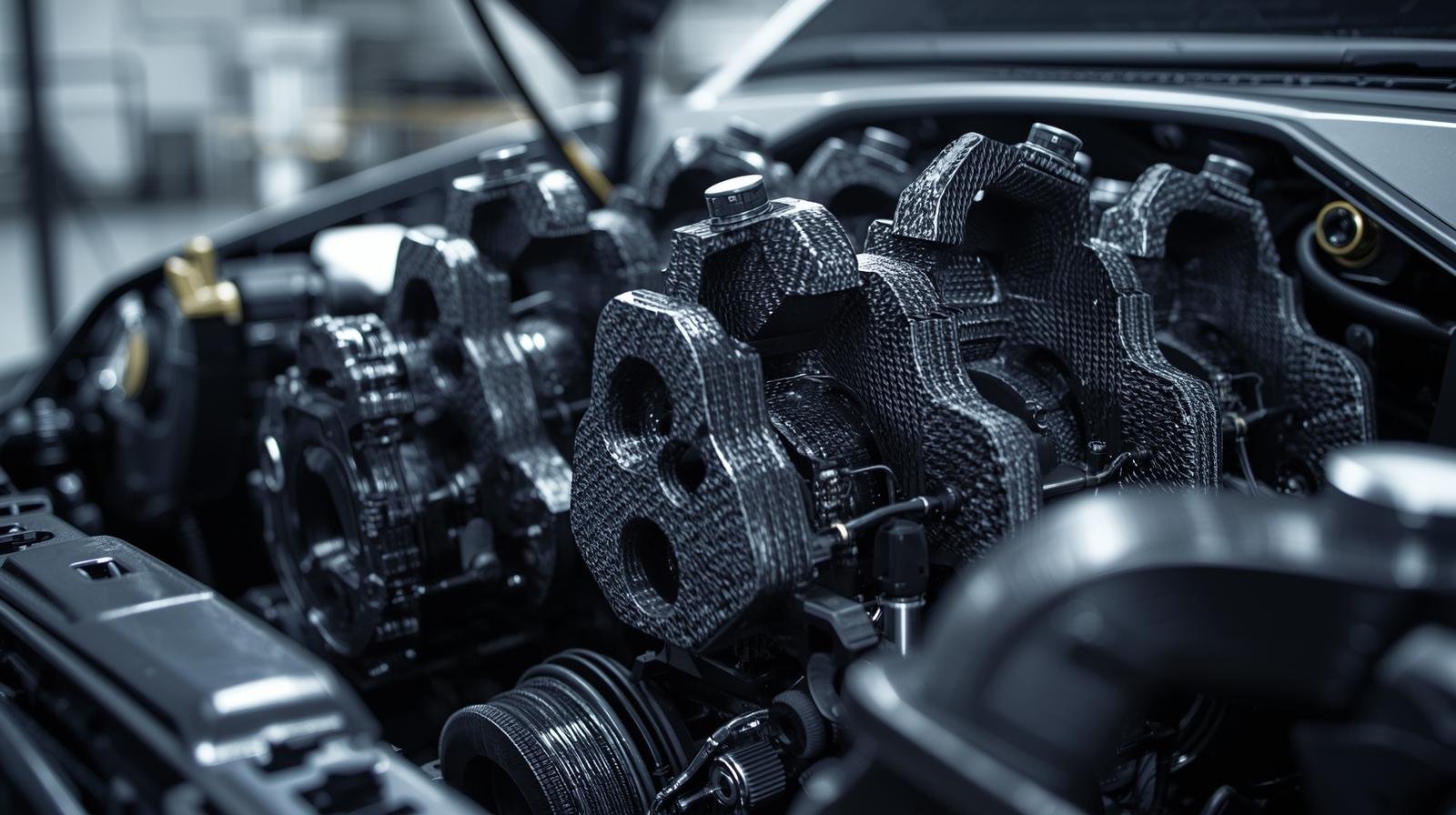

Components that are produced through additive manufacturing technology are known as 3D printed car parts. It is based on a digital 3D representation as the layers of the object are made in real life by printing it out using plastic, metal or resin. In contrast to the old manufacturing processes where the shape, surfacing, or materials are cut or shaped by the use of a mold or a machine, 3D printing creates parts at the bottom.

The 3D printing has been an indispensable instrument of developing customized, lightweight, and intricate car components in the world of automobiles. The applications of 3D printing car parts are unlimited, starting in engine parts to interior details.

Benefits of 3D Printing Car Parts

Customization:

The possibility to produce customized pieces is one of the most important benefits of 3D printing. It may be a design that is one-of-a-kind or it may be a material that is unconventional, 3D printing can be very customizable, in a manner that conventional production processes cannot.

Cost-Effective:

Mass production with the traditional manufacturing of cars is costly as it requires a lot of molds and tools, whereas 3D printing makes such tools unnecessary and reduces costs of production. This especially helps in small batches or customized parts production where conventional manufacturing maybe not cost effective.

Faster Prototyping

The process of prototyping is shortened with the use of 3D printing. The engineers can print a model quickly and test its fit and functionality and do all these without necessarily molding a new one in each instance. This would reduce the development time greatly.

Material Efficiency:

Conventional manufacturing techniques can be very wasteful in terms of the material used to make part. 3D printing on the other hand can utilize only the amount of material needed to manufacture the part layer by layer, which is less wasteful and makes the process environmentally friendly.

Lightweight Designs:

A great number of 3D printing technologies permit the production of lightweight components with complicated geometries that would not be possible to produce previously through conventional production. This is important in the motor industry where lessening the weight of the vehicle can enhance fuel efficiency and the overall performance of the vehicle.

Types of 3D Printed Car Parts

- Engine Components:

3D printing technologies are applied to print light engine parts including intake manifolds, turbocharger components and cooling components. The sections can be developed in order to enhance airflow, minimize weight, and enhance efficiency.

- Exterior Body Parts:

Examples of exterior car parts that can be 3D printed are custom bumpers, grilles, and side mirrors. The 3D printing process is suited to customization of cars due to the ability of creating complex and unique designs.

- Interior Components.

3D printing can also be applied in the interior of cars. Components like dashboard, center consoles and even air vents can be designed and manufactured with the exact specifications of fitting in perfectly.

- Performance Parts:

Most car lovers resort to 3D printing to produce performance car parts such as exhaust or suspension components. These segments are lightweight and designed to meet the requirements of particular vehicles.

- Model Car Parts:

In addition to functional car parts, 3D printing is popular too in creating model car parts. This assists hobbyists and manufacturers to make model cars that are detailed and realistic with regards to display or prototype.

Features and Uniqueness of 3D Printed Car Parts

Although 3D printing in the automotive industry is still developing, it is already having amazing opportunities. Why 3D printed automotive parts are so special? We shall discuss the features and peculiarities that distinguish 3D printed car parts on the one hand, as compared to the conventional ways of manufacturing automobile parts of the automotive industry.

1. Precision and Accuracy

The accuracy and precision are amazing in 3D printing of car parts. This technology involves a computerized model in digital form that directs the printer so that all the components are made in the precise form. The layers are stacked to a level of detail that the final product may even surpass the level of precision introduced with a traditional manufacturing process where certain processes may introduce slight variations through human error, or due to the constraints of the tools used.

2. Complex Geometries

The possibility to develop very complex geometries that could otherwise be hard to create, or even impossible, with conventional manufacturing techniques is one of the particularities of 3D printing. It could be a lightweight lattice structure of an engine component or a more detailed and complex component of the interior, 3D printing gives engineers the ability to create car components with complex shapes and internal features that will be operational and attractive at the same time.

3. Lightweight Components but no loss in strength.

The other outstanding aspect of the 3D printed car parts is that they are lightweight and strong at the same time. Conventional car components are generally made focusing on strength and durability, which makes them thick and heavy. 3D printing enables the manufacture of components with inner structures that save on weight whilst holding strong. It creates the ability to make the overall vehicle lighter thereby making it more fuel efficient and handling better without compromising in safety and durability.

4. Individualization and Personalization.

Any car lover understands the role of customization. The customization of the 3D printed car parts can be done on a scale never seen before, be it the interior of the car, the performance aspects, or the outlook of the car. The drivers would be able to develop unique designs that would fit their style, requirements, and tastes. It could be a special dashboard unit, a wheel of a different design, or a completely one-off part of the engine, but 3D printing allows it to be more easily realized.

Besides, 3D printing may be applied in the production of parts with specific car specifications. In case of restoring a classic car, 3D printing can assist, and recreate the parts that are no longer in the market and make your restoration as similar to the original as possible.

5. Quickness and Agility in manufacturing.

The speed is a major aspect of 3D printed car parts attractiveness. The conventional manufacturing processes take into consideration molds, machineries and a considerable lead time in order to manufacture parts. In 3D printing, though, a manufacturer can take a fraction of the time to go through with the design and production process. This ability to prototype fast gives it the ability to create, refine designs and then mass-produce, cutting the time-to-market.

As an example, engineers may readily print and test new parts, and make changes accordingly. This does not only reduce the time taken to develop the product it also enables manufacturers to react to customer feedback and changing trends faster than using traditional methods.

6. Reduced Material Waste

Conventional manufacturing operations like casting or machining tend to wastage of a significant amount of material. Conversely, in 3D printing, the material is simply used to add layers of the part one at a time. The additive manufacturing technology creates little waste and thus it is more eco-friendly compared to other traditional methods. Also, the fact that it is possible to recycle some materials that are employed in 3D printing also adds to the attempts at sustainability in the automotive industry.

7. Economy in the low-volume production.

The cost of small quantities of car parts has long been prohibitive because of the cost of using expensive molds and tooling. But with 3D printing, these initial costs are eliminated and as a consequence, it is a fantastic alternative when the quantity is low or it is a one-off production. This is best suited in making parts of replacement, limited production parts of a vehicle, or even special parts that do not need mass-producing.

As an illustration, the 3D printing technique can also be applied by niche auto producers or hobbyists to print small quantities of custom parts at very low prices compared to the expensive process of conventional manufacturing. This renders 3D printing a good solution on both small and large automotive projects.

8. Increased Designing and Innovating.

Auto innovation is normally a long process because the process of designing, prototyping and testing of new components is very complicated. In 3D printing, engineers and designers are able to do multiple iterations of designs, concepts, and prototype refinement faster. This will allow quicker feedback loop to bring the innovative ideas to life faster.

Such a process fosters greater experimentation, and thus, the car design breakthroughs are creative. Actually, other auto firms already have been relying on 3D printing 1 to 3 prototype futuristic car parts that would be either too expensive or time consuming to make through conventional manufacturing processes.

Uniqueness of 3D Printed Car Parts in Customization

In contrast to the traditional approaches where the production lines are usually massive and the design-related requirements are strict, 3D printed car components offer full liberation in regards to design and functionality. Either a single, complex piece or an entire assembly of bespoke parts, the flexibility of 3D printing will enable car enthusiasts, hobbyists and professional manufacturers to create items at the precise specifications.

- Vehicle Restoration: In the case of those who are restoring vintage or classic vehicles, the parts of the vehicle that are no longer produced because of the manufacturing company going out of business can be recreated by 3D printing so that the vintage appearance and functionality of the vehicle is maintained.

- Personalized Designs: 3D printed car parts can be used to add that personal touch by owners of car personalization, such as custom grilles, personalized shift knobs, and so forth.

- Enhancement of Performance: The 3D printing can be applied in production of lightweight and high-performance parts that can add speed, fuel consumption or handling of a vehicle.

Where to Find 3D Printed Car Parts For Sale?

With the 3D printing gaining popularity in the automotive industry, several businesses and individuals have become sellers of 3D printed car parts. You can find many different choices whether you are planning to fill out a car build with some custom parts, or you are in need of a replacement part to replace a damaged component or you are just planning to improve the performance of your car. The most general channels used to buy 3D printed car parts are:

- Internet Marketplaces: The most common ways of selling 3D printed parts include eBay, Amazon and automotive industry specific automated websites.

- 3D Printing Services: These worksheets enable your company to print something you have created or to select one off the shelf to have printed and sent to you. You can pay just a little and get high quality work.

- Car manufacturers: Large automobile firms and aftermarket parts manufacturers are now considering selling 3D printed car parts to the end user.

How 3D Printing is Changing the Car Industry?

Along with the invention of 3D printing technology, the way cars are manufactured has not only changed, but the way vehicles are designed is also changing. The conventional approaches of automotive design and production would tend to take a long period to produce an item, the tooling would be costly, and the complexity of the parts would be restricted. The 3D printing can be used to test new designs, enhance the performance of a vehicle, and optimize the entire manufacturing process in car manufacturers.

There is also 3D printing which gives owners and enthusiasts of cars the flexibility of customizing their cars more readily. Having the ability to print a unique component or even make a replacement component in case of a broken one, the availability of the 3D printed part of a car provides consumers with more choices than at any other time.

Why Choose 3D Printed Car Parts?

- Unparalleled Design Flexibility – This is because 3D printed car parts are not only able to produce complicated, custom-built designs unlike traditional parts. This aspect will enable complete freedom of design whether you are a car enthusiast or a manufacturer.

- Reduced Prototyping and Small- Run Costs 3D printing is an affordable technique of producing prototype components and small production batches. Manufacturers can save on money and time without any molds and tools, which are costly.

- Innovative Materials- New 3D printing technologies can enable the utilization of any type of material, such as metals and composite that offer strength, durability and flexibility in the end product.

- Green – 3D printing helps to make the automotive industry more green as the amount of material waste decreases, and the recyclable material can be used.

What kind of materials are applied in 3D printing of car parts?

The car parts produced in 3D printing can be manufactured using any type of material, such as plastics (ABS and nylon), metals (aluminum and titanium), or using resin. Depending on the performance, durability and the functions of the part, the material can be chosen.

What is the price of a car part that has been 3D printed?

The prices of a 3D printed automotive part are determined by its material, complexity, size, and the design being a one-off or an off-the-shelf part. Custom parts are potentially more costly because of the design and time of production.

Are 3D printed car parts as durable as conventional car parts?

Yes, a substantial amount of 3D printed car parts is as strong as their counterparts are. Certain 3D printing processes, particularly those based on metal or high-density plastic, make components with the same or greater strength than those produced through traditional production processes.

Is car manufacturing the future of 3D printing?

One of the major components of the future of the automobile manufacturing is certainly 3D printing. It provides cost savings, quicker prototyping and capability of producing custom components that would have been hard or not possible to make using the conventional techniques.

Is it possible to use 3D printing to repair automobiles?

Yes! In case you have a damaged or faulty part, you can make a new part by printing using 3D. There are several users of 3D printing in the process of repairing old automobiles or making a single piece of work.

Conclusion

Concluding, car parts that are 3D printed are changing the face of the automotive industry as it is giving them a degree of customization, accuracy and affordability that conventional manufacturing techniques could never achieve. This new technology is changing the way vehicles are assembled, repaired and customized by reducing production times, creating complex and lightweight design and personalization of vehicles.

With the future of 3D printing still to be seen, the possibilities it represents to both car manufacturers and car enthusiasts is endless, and the future of automotive solutions will be more sustainable, efficient and creative. Be it designing of custom components, driving the vehicle to perform better, or making the manufacturing processes smoother, 3D printed car parts are certainly the future of the automobile industry.